With the technological innovations in fields such as electronic devices, composite materials, adhesives, etc., the performance requirements for epoxy resins are becoming increasingly diverse and sophisticated, with a growing demand for higher toughness. Thus, the cured products of cycloaliphatic epoxy resins need to be further toughened. Due to their rigid structure, cycloaliphatic epoxy resins cured products form a dense three-dimensional network with high crosslinking density, making them somewhat brittle. There are numerous research findings on improving the toughness of epoxy resins recorded in literature and patents.

The table below mainly lists toughening methods:

| Technical Solution | Viscosity | Compatibility | Operational Toughened Performance | Principle | |||

| Tg | Transparency | Toughening Effect | |||||

| Softener | Low | Good | Good | Significant decrease | Good | Stable, modulus decreases | Reduce rigidity and crosslink density |

| CTBN Series | High | Good | Average | Decrease | Bad | Stable, weather resistance decreases | Introduce rubber phase to form island structure |

| CSR | High | Generally Low | Average | Slight decrease | Bad | Stable, difficult to disperse | Introduce rubber particles to form microphase separation |

| Filler Materials | Solid | Generally Low | Average | Slight decrease | Bad | Unstable, phase separation is difficult to control | Introduce copolymer particles to form microphase separation |

| Microparticles | Solid | Bad | Acceptable | No decrease | Ok | General, relatively rigid | Introduce rigid particles |

Current methods mainly target Bisphenol A type epoxy resins. Our company, one of the top cycloaliphatic epoxy resin manufacturers in the market, refers to but is not limited to these methods. For cycloaliphatic epoxy resins toughening, further enhancements are needed in practical applications, including tensile strength, elongation at break, fracture toughness, and impact strength. Simultaneously, the heat resistance must not be significantly compromised. Special applications require maintaining excellent transparency, which presents more challenges for product development.

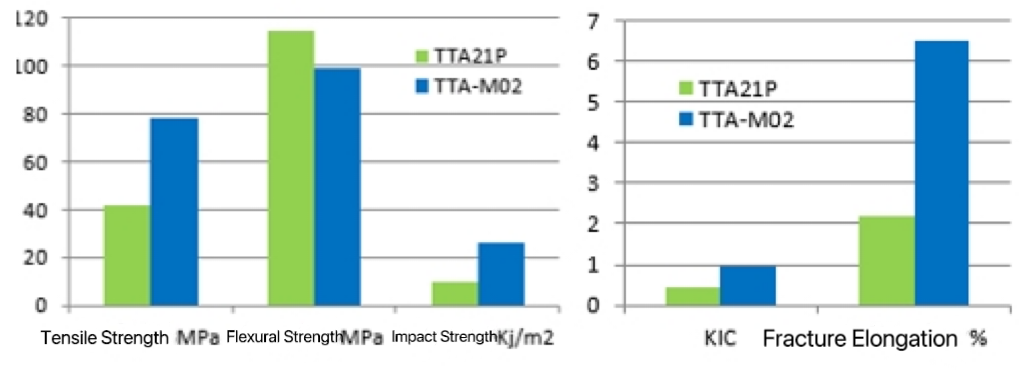

The product's impact strength has been significantly improved compared to the TTA 21 series. The resistance to low-temperature cracking has been elevated, with the anhydride-cured elongation at break tripled and impact strength increased by 100%, while Tg remains no less than 180°C, maintaining high heat resistance.

Performance table for the anhydride curing system:

| Item | TTA-M02 | TTA21P |

| Appearance | Milky White | Clear and Transparent |

| EEW (g/eq) | 160 | 130 |

| Viscosity (25°C/cps) | 750 | 240 |

| Tg-DSC (°C) | 185 | 205 |

| Tg-DMAE (°C) | 181 | 198 |

| Flexural Strength (MPa) | 99 | 115 |

| Tensile Strength (MPa) | 78 | 42 |

| Tensile Break Elongation (%) | 6.5 | 2.2 |

| Fracture Toughness (Kc, MPa-m²) | 0.95 | 0.42 |

| Impact Strength (Kj/m²) | 26.1 | 9.5 |

| Remarks | (1) Anhydride: MHHPA; (2) Curing Conditions: 100°C/2hr + 140°C/2hr + 180°C/1hr |

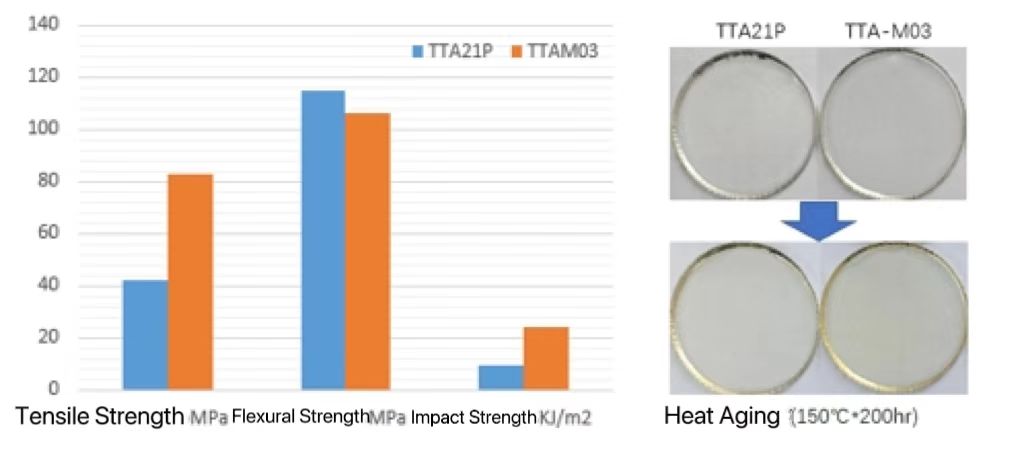

In common toughening methods, rubber phases or block copolymers form phase-separated structures in the cured epoxy resin, achieving toughening. The formation of these phase-separated structures is accompanied by light scattering at the interface, often leading to reduced transparency. Thus, they are unsuitable for applications requiring high optical performance. To meet such demands, we developed TTA-M03, the cycloaliphatic epoxy resins that maintains a Tg of 180°C while significantly improving elongation at break, achieving a tensile strength of above 80MPa, and enhanced adhesion strength. Additionally, it boasts excellent transparency and heat-aging resistance, showing no significant change in appearance after a 150°C/200h heat-aging test.

Performance table for the anhydride curing system:

| Item | TTA-M03 | TTA21P |

| Appearance | Clear and Transparent | Clear and Transparent |

| EEW (g/eq) | 170 | 130 |

| Viscosity (25°C/cps) | 400 | 240 |

| Tg (Glass Transition Temperature, °C) | 180 | 205 |

| Flexural Strength (MPa) | 104 | 115 |

| Tensile Strength (MPa) | 83 | 42 |

| Tensile Break Elongation (%) | 6.7 | 2.2 |

| Fracture Toughness (Kc, MPa-m²) | 0.67 | 0.42 |

| Impact Strength (K/m²) | 24.2 | 9.5 |

| Transmittance (%) | 91.6 | 91.8 |

| Remarks | (1) Anhydride: MHHPA; (2) Curing Conditions: 100°C/2hr + 140°C/2hr + 180°C/1hr |

From the above, it is evident that TTA-M03 achieves a good balance between the heat resistance and excellent mechanical properties and transparency of the cured system. It is applicable in fields like composites, electronic encapsulation, adhesives, etc.

TETRA is a global leader in specialty epoxy resins supply, focusing on high-end epoxy resin materials. Our products not only meet domestic market demands but are also sold in over 50 countries worldwide. Their applications span multiple industries, such as UV-cured coatings/inks, composites, electronic and electrical insulation, semiconductor encapsulation materials, and 3D printing additive manufacturing. We are dedicated to setting a new benchmark for the application of chemical new materials in China, aiming to guide domestic demand and promote the industrial upgrade of epoxy resins in China.

For questions regarding cycloaliphatic epoxy resins related products and toughening technologies, feel free to reach out to us to enhance the application of aliphatic epoxy in formulations and enhance product value.