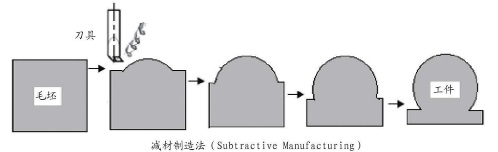

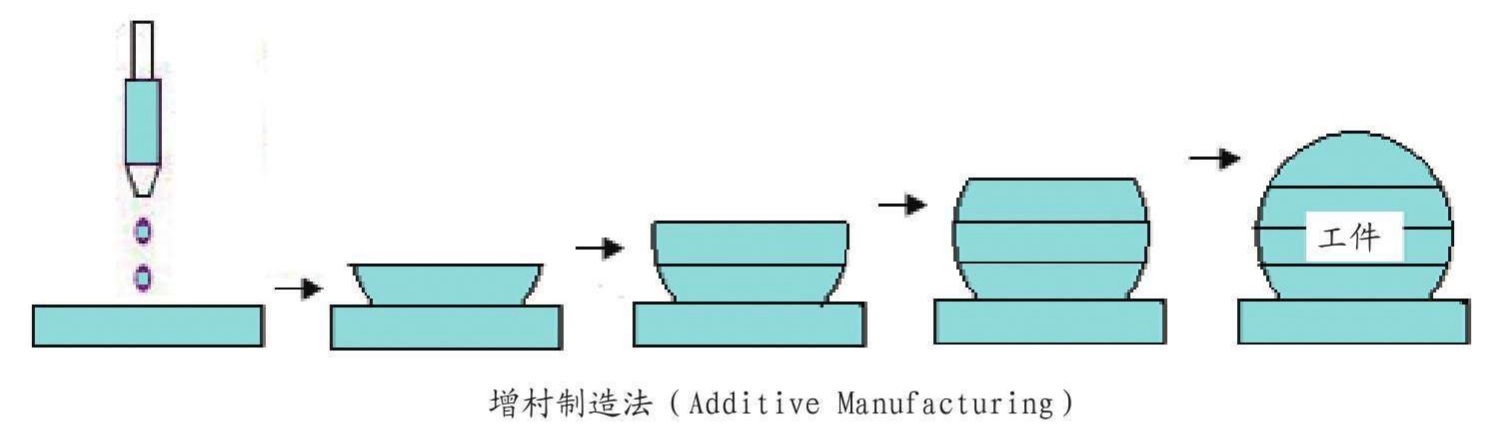

3D printing is a rapid prototyping technology that is fundamentally different from traditional subtractive manufacturing methods. By adding materials and based on three-dimensional CAD model data, it typically employs a layer-by-layer manufacturing approach to directly create a three-dimensional physical model that is entirely consistent with the corresponding mathematical model.

Photocuring 3D printing technology is one of the cost-effective, highly efficient, and high-quality forming technologies within the realm of 3D printing. It has broad application prospects in medical devices, the automotive industry, jewelry casting, mold manufacturing, aerospace, and other fields. Currently, the mainstream photocuring 3D printing technologies include Stereolithography (SLA), Digital Light Processing (DLP), and Selective Light Exposure (LCD).

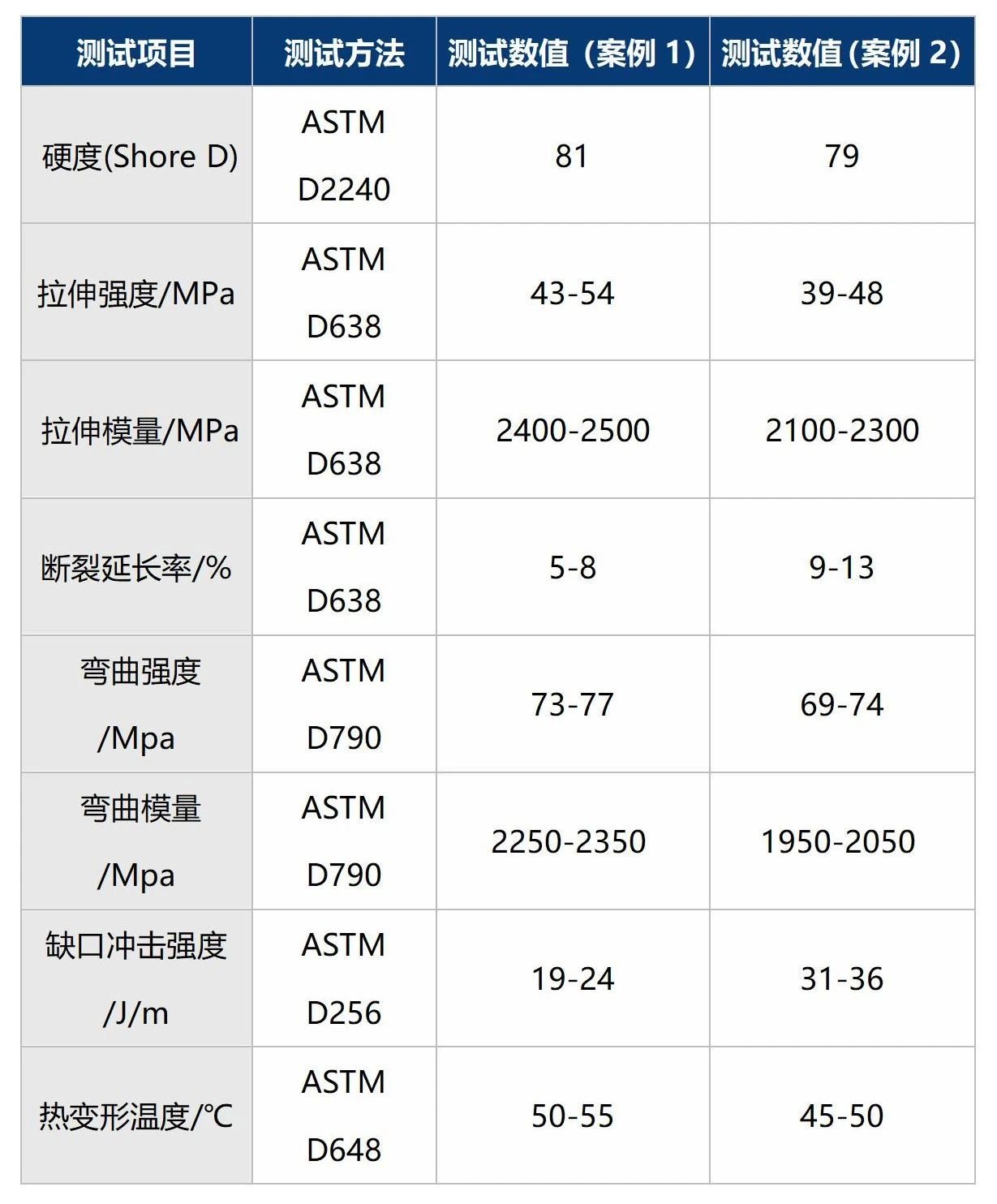

The forming materials for photocuring 3D printing are liquid photosensitive resins, primarily composed of prepolymer resin, diluent monomer, photoinitiator, and additives. Cycloaliphatic epoxy resins are widely used in SLA-type 3D printing photosensitive resins due to their characteristics of low viscosity, low volume shrinkage, and fast cationic curing speeds. The representative cycloaliphatic epoxy resin is TTA21. Toughness is a crucial evaluation indicator for 3D printing materials. To further improve the toughness of 3D printing materials, flexible cycloaliphatic epoxy resins like TTA26 can be selected. The main indicators are as follows:

Compared to the classic cycloaliphatic epoxy resin TTA21, TTA26 has better flexibility. It not only improves the material's toughness but also meets the requirements of rapid cationic curing. It is mainly used in 3D printing materials that demand higher toughness. In the comparison cases below, Case 1 primarily uses cycloaliphatic epoxy resin TTA21, while Case 2 primarily uses cycloaliphatic epoxy resin TTA26. From the following data, it is evident that the toughness of the material is significantly improved after curing when the photosensitive resin liquid consists of TTA26.