New materials are known as "industrial magic". Every revolutionary new technology and new material application will inevitably drive a new wave of industrial revolution. In recent years, with the rapid development of UV light-curing technology, it has been widely used.

In order to fully embrace this wave of technological evolution, Jiangsu Tetra cycloaliphatic epoxy resin manufacturer invested in the establishment of a cycloaliphatic epoxy application technology service center in Songjiang, Shanghai in 2019, equipped with photo-DSC, rheometer, photo-DEA, ATR-FTIR, and track-type UV curing machine and other equipment, aiming to provide technical support and services for downstream thermosetting/UV curing customers. The center has been operating for nearly two years and has successfully provided satisfactory technical solutions to more than 100 domestic and foreign users. However, in the process of technical services, we have also found that domestic users have uneven understanding of the curing technology of cycloaliphatic epoxy, especially UV cationic curing technology. Therefore, our technical team has specially compiled a series of materials for the application guide of cycloaliphatic epoxy products to promote the application knowledge of products. Taking the most widely used cycloaliphatic epoxy monomers TTA21(3,4 epoxycyclohexylmethyl 3,4 epoxycyclohexane carboxylate) and TTA26(Bis (3,4-Epoxycyclohexylmethyl) Adipate) as examples, this article summarizes the factors that many users are concerned about in the UV cationic curing process, for readers' reference.

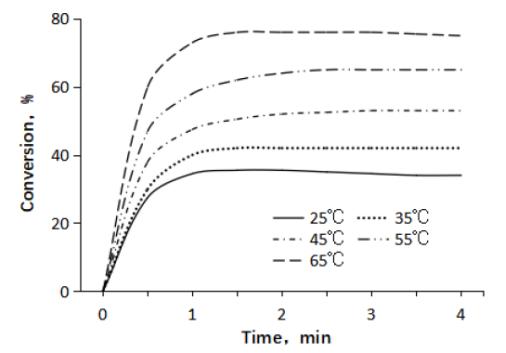

Testing conditions: Photo-DSC, mercury lamp, light intensity 60mW/cm²

TTA21: TTA UV-692=100:5

Experimental phenomena: The conversion rate increases significantly as the temperature rises from 25℃ to 65℃.

Reasoning: With the increase in temperature, the molecular thermal motion of the active species is increased, which increases the collision probability, accelerates the polymerization rate, and thus increases the conversion rate.

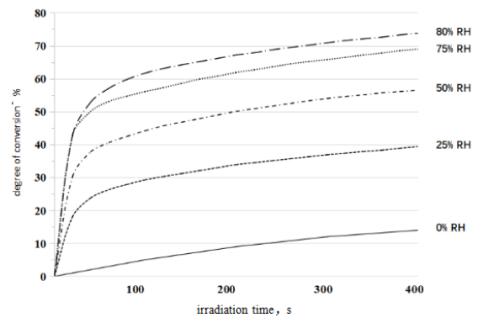

Testing conditions: Photo-DSC, mercury lamp, light intensity 60mW/cm²

TTA21: TTA UV-692=100:5

Experimental phenomena: The conversion rate gradually increases as the humidity increases.

Reasoning: Moisture has a chain-extending effect, which overcomes the steric hindrance effect of cycloaliphatic epoxy, making the epoxy group more prone to attack the carbon cation, thus increasing the conversion rate.

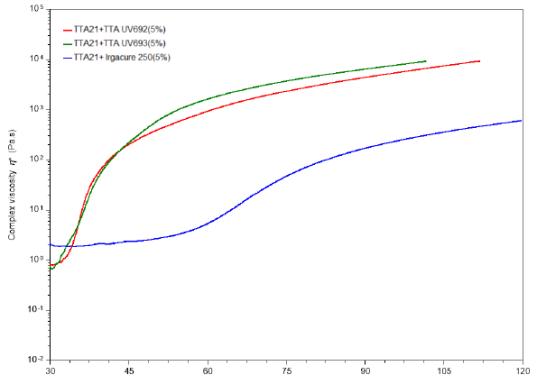

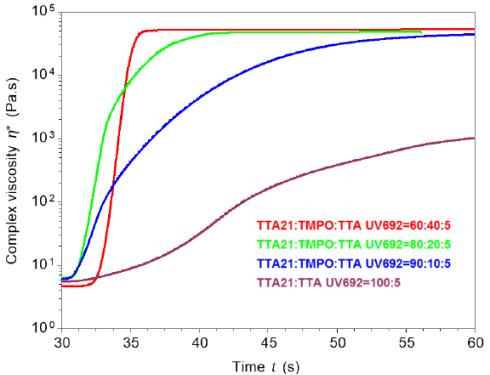

Testing conditions: Photo-DHR, mercury lamp, 850mW/cm2

TTA21: Cationic photoinitiator=100:5

Experimental phenomena: Different cationic photoinitiator types have different polymerization reaction rates. As can be seen from the figure, the activity of the photoinitiator TTA UV692 (sulfonium antimonate) > TTA UV693 (sulfonium phosphate) > Irgacure 250 (iodonium salt).

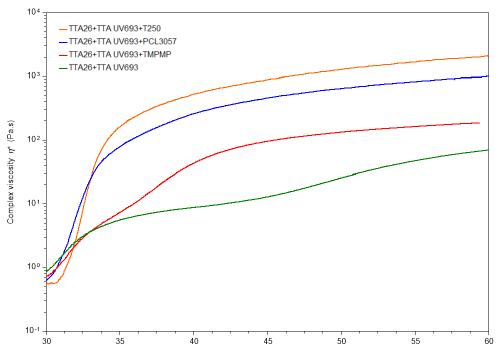

Testing conditions: Photo-DHR, mercury lamp, 850mW/cm2

TTA26: TTA UV693: Polyol=100:5:10

Experimental Phenomenon: As can be seen from the graph, the addition of polyols in the formula has a promoting effect on the polymerization rate. Different types of polyols have different effects on the polymerization reaction rate, with T250 (PTMG) > PCL3057 > TMPMP having the most promoting effect.

Reason Analysis: Polyols, as chain transfer agents, react with epoxy oxides to increase the polymerization reaction rate.

Test Conditions: PhotoDHR, Mercury Lamp, 850mW/cm2

Experimental Phenomenon: The addition of oxirane in the formula has a promoting effect on the polymerization rate. With the increase of the proportion of oxirane, the curing rate increases accordingly.