With the trends of diversification, integration, miniaturization, and high performance in electronic components, higher demands are placed on the performance of electronic adhesives. Since most electronic components are sensitive to temperature and cannot withstand high temperatures, the curing process requirements for adhesives are medium to low temperature rapid curing. In addition to excellent bonding strength and reliability, adhesives are expected to have low yellowing and good storage stability.

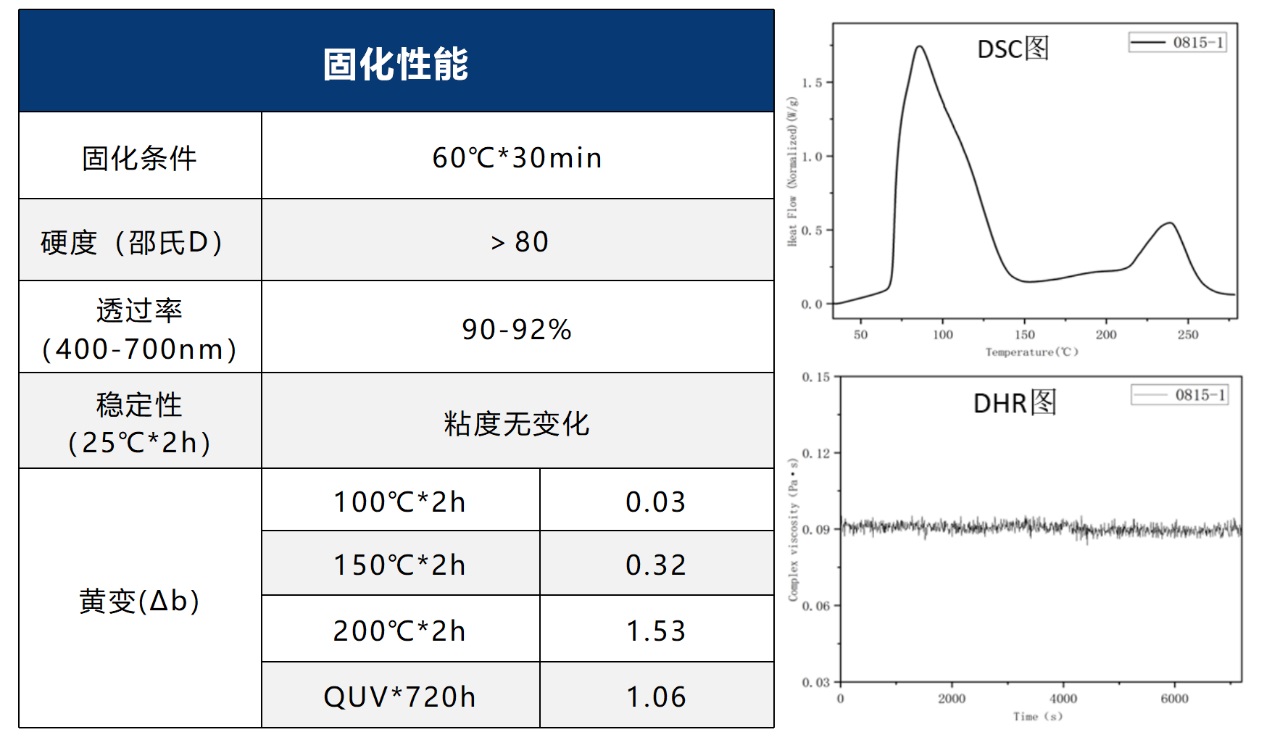

For single-component medium-temperature epoxy adhesives, there is a common problem of slow curing at medium temperatures (60°C-80°C) or short operable time at room temperature. To address these issues, TTA cycloaliphatic epoxy resin thermal cationic curing can be used. By combining cycloaliphatic epoxy resin with a high-performance thermal cationic initiator, rapid curing within 30 minutes at 60°C can be achieved, and the system's stability is relatively good, offering a long operable time with no change in viscosity within 2 hours at room temperature. Additionally, the cured product is highly transparent, exhibits excellent yellowing resistance, and has potential application prospects in the optoelectronic display field.