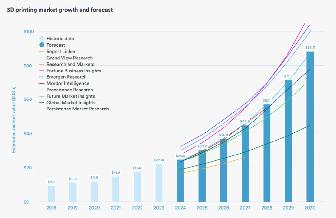

In recent years, 3D printing technology has rapidly developed and gradually become an indispensable part of modern manufacturing. According to the latest data from the "2024 3D Printing Trends Report" released by Protolabs, the 3D printing market is growing at an astonishing speed and is expected to reach a market size of $57.1 billion by 2028.

What is the driving force behind this growth? This article will delve into the key findings in the report and provide an outlook on industry trends for 2024.

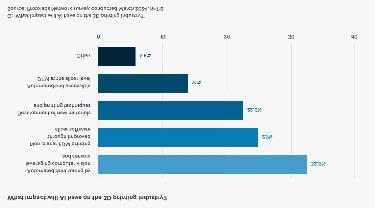

The report points out that the speed and flexibility of 3D printing remain the attractiveness of this technology. Almost half (47%) of the respondents stated that delivery time is their main reason for choosing 3D printing over other manufacturing methods - this proportion has increased from 44% in the previous year to 47%. Easy access to technology (43%) and geometric complexity (41%) are other important factors, and price is also one of the determining factors, increasing from 29% in the previous year to 33%.

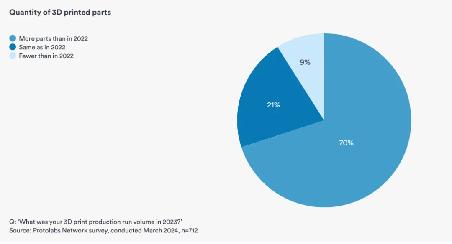

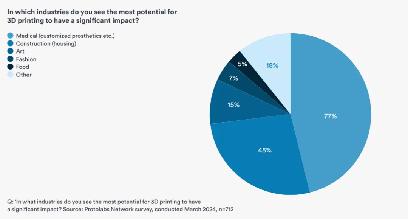

In addition, 82% of people reported that 3D printing helped them save a significant amount of costs in the manufacturing process. In addition, 70% of the surveyed companies stated that they will print more parts in 2023 compared to the previous year, with the medical sector particularly promising.

Market growth exceeds expectations

The report shows that the size of the 3D printing market in 2023 was $22.14 billion, an increase of 26.8% from $17.46 billion in 2022. This far exceeds expectations and is 10.5% higher than the market size predicted in last year's report for 2023. Based on a compound annual growth rate of 21%, it is expected that the market size will reach $24.8 billion in 2024 and $57.1 billion by the end of 2028.

Expansion towards production applications

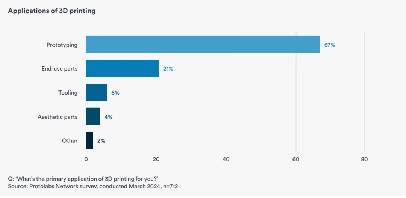

The report emphasizes that 3D printing is gradually shifting from prototype design to production applications. 67% of respondents stated that they use 3D printing for prototype design, while 21% are used for end use parts, but the distribution of these applications varies by industry. The industries with the highest adoption rate of end use parts are transportation (33%), robotics (30%), and industrial automation (27%). In the design industry, 9% of respondents use 3D printing for the production of aesthetic parts, which is more than twice the average level.

FDM remains the most commonly used

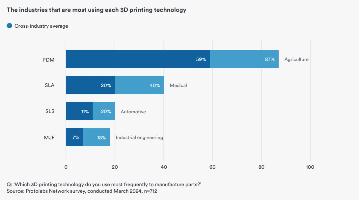

Another focus of the report is the recognition of the application of various technologies. 3D printing technology varies in material selection, surface finish, durability, manufacturing speed, and cost. The most commonly used technologies by respondents are FDM (59%), SLA (20%), SLS (11%), and MJF (7%). By industry, 87% and 79% of respondents in the agricultural and construction industries respectively use FDM the most frequently, 42% and 40% in the medical industry use FDM and SLA, 25% in the biotechnology industry use SLA, 20% in the automotive industry use SLS, and 18% and 15% in the industrial engineering and electronics industries use MJF, respectively.

Comprehensive coverage of large and small fields

At the microscale level, 3D printing is the only technology that can achieve certain geometric shapes and quantities; This potential continues to be utilized, especially in the medical and dental fields. At the other extreme, there are exciting new developments in large-scale printing of plastics and metals, demonstrating enormous potential in fields such as furniture, ships, and architecture. For example, printing houses using large-scale epoxy resin 3D printing technology can significantly reduce labor costs and material waste.、

Artificial intelligence has enormous potential

Artificial intelligence (AI) is rapidly changing the 3D printing industry. AI can not only improve printing quality and efficiency, but also optimize design processes. In addition, AI has shown great potential in generating designs, topology optimization, and multi physics process simulation. Nearly one-third of the respondents believe that automatic printing adjustment is the biggest impact brought by artificial intelligence, followed by non planar FDM printing achieved through improved slicing software (25%).

With the rapid growth of the market, continuous innovation of technology, and continuous expansion of application fields, 3D printing will continue to lead the transformation of the manufacturing industry. Hybrid manufacturing technology combines additive manufacturing and CNC machining, providing a wider range of manufacturing possibilities. Multi Tetra material printing allows for the combination of materials with different properties within an object, further expanding the application range of 3D printing. In addition, metal printing technology is also constantly developing, especially in high demand fields such as aerospace, automotive, and medical.