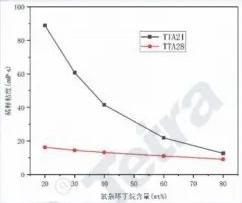

Ink is one of the largest pollutants in the printing industry with a large amount of VOCs endangering the atmospheric environment. Therefore, green printing technology and eco-friendly ink are imperative.UV-LED inkjet, as one type of eco-friendly ink, can be divided into free radical systems and cationic systems. Compared to the former, the cationic system has advantages such as oxygen inhibition resistance, low shrinkage, dark cure, and is more suitable for UV-LED inkjet. Currently, in the cationic system,cycloaliphatic epoxy resins are primarily TTA21, with a viscosity above 200mPa·s (25℃), requiring a large amount of reactive diluting monomers during use to meet the inkjet viscosity requirement of<30mPa·s, resulting in thecycloaliphatic epoxy resins not fully exerting their properties, leading to unsatisfactory curing speed, adhesion, solvent resistance, and heat resistance for inkjet. To meet the application needs for UV-LED cationic inkjet, Tetra, one of the leading cycloaliphatic epoxy resin manufacturers, developed a series of cycloaliphatic epoxy resins with lower viscosity and faster curing speed compared to TTA21.

TTA20 | TTA22 | TTA28 | TTA800 | |

Viscosity mPa·s(25℃) | 4-20 | 5-30 | 10-30 | 50-70 |

Epoxy Equivalent | 80-100 | 70-80 | 70-100 | 100-110 |

Features | Bio-based Ultra low viscosity | Low viscosity Fast curing | Low viscosity Fast curing, highTg | Ultra-fast curing, HighTg, high hardness, low viscosity |

Structural Formula |

|

| / | / |

Taking TTA28 as an example, its performance in UV-LED cationic inkjet applications is examined, including formula viscosity, storage stability, curing speed, adhesion (304 stainless steel), solvent resistance, and heat resistance.

Formula composition: (TTA21/28+TTA201+TTA101): pigment paste: initiator: photosensitizer: additive=100:15:4:1:2

Figure 1: amount and formula of oxetane

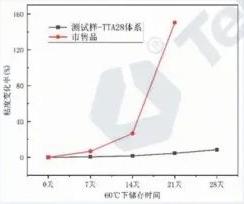

Figure 2: Storage Stability

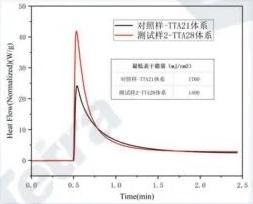

Figure 3: Curing Speed (395nm LED Light Source)

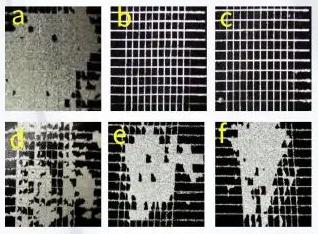

| Experiment No. | Ratio of Cycloaliphatic Epoxy Resin to Oxetane | Adhesion Grade (0: Best, 5: Worst) | |

| 24h | 7 Days | ||

| Control Sample (a) | TTA21/TTA201/TTA101=40/50/10 | 5 | 5 |

| Control Sample1(b) | TTA28/TTA201/TTA101=80/10/10 | 0 | 0 |

| Control Sample2(c) | TTA28/TTA201/TTA101=70/20/10 | 0 | 0 |

| Control Sample3(d) | TTA28/TTA201/TTA101=60/30/10 | 1 | 5 |

| Control Sample4(e) | TTA28/TTA201/TTA101=40/50/10 | 5 | 5 |

| Control Sample5(f) | TTA28/TTA201/TTA101=20/70/10 | 5 | 5 |

Table 4: Cross-Cut Adhesion Test Grades

Conditions: 304 stainless steel substrate, 10μm film thickness, 395nm LED light exposure (5000mJ/cm²), tested according to GB/T 9279-2007.

Figure 5: Cross-Cut Adhesion Analysis (7 Days)

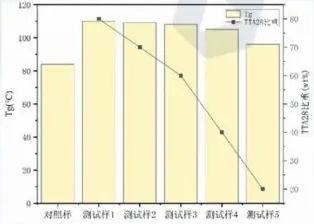

Figure 6: Tg (DMA Thin Film Tensile Method)

| Experiment No. | Solvents | |

| Ethanol | MEK | |

| Control Sample | >100 wipes | >50 wipes |

| Test Sample 2 | >100 wipes | >50 wipes |

Table 7: Solvent Wipe Resistance

Conditions: 304 stainless steel substrate, 10μm film thickness, 395nm LED light exposure (5000mJ/cm²), tested according to GB/T 23989-2009 (1kg load, 60rpm).

TTA28, as an ultra-low viscosity cycloaliphatic epoxy resin, serves both as a film-forming resin and a diluent in UV-LED cationic inkjet printing. This specialty resin chemical features fast curing speed, excellent adhesion, good solvent resistance, high-temperature resistance, and good storage stability. Additionally, TTA20, TTA22, and TTA800 also exhibit similar properties, making them valuable for cationic inkjet printing applications.