Electrical casting materials refer to a type of epoxy insulation material used for casting insulators, transformers, or dry-type transformers. The formulation uses an anhydride-curing system with epoxy resin, primarily employing Bisphenol A epoxy resin, which offers advantages such as good processability, high cured material strength, good corrosion resistance, and excellent electrical properties. However, due to limitations in process conditions and the end-use environment of the products, issues such as high system viscosity, restricted powder addition ratios, and insufficient heat and weather resistance often arise. Cycloaliphatic epoxy, with their epoxy groups directly attached to aliphatic ring structures, can significantly increase the crosslinking density of the cured material, thereby providing higher heat resistance, weather resistance, and electrical insulation properties. Additionally, cycloaliphatic epoxide have extremely low viscosity and a significant dilution effect. Therefore, cycloaliphatic epoxy can compensate for the shortcomings of Bisphenol A epoxy resin in electrical casting material systems. When used together, they can improve the material's processability and enhance the safety of the final epoxy electrical insulation products.

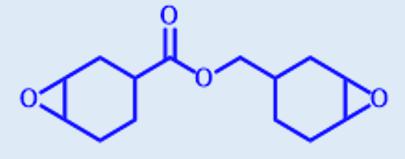

Chinese Name: 3,4-Epoxycyclohexylcarboxylic acid-3',4'-Epoxycyclohexyl methyl ester

English Name: 3,4-Epoxycyclohexylmethyl- 3',4'-Epoxycyclohexane Carboxylate

CAS No.: 2386-87-0

Structural Formula:

Molecular Weight: 252.31

Molecular Formula: C14H20O4

Grade | TTA21S | TTA21L | TTA21P |

Appearance | Colorless transparent liquid | ||

Content | 90% min | 95% min | 97% min |

Epoxy Equivalent (g/mol) | 128-145 | 126-135 | 126-135 |

Color (APHA max) | 100 | 50 | 50 |

Viscosity (cP) | 180-450 | 220-300 | 220-300 |

Moisture | 0.05% max | 0.05% max | 0.05% max |

Acid Value | 0.1% max | / | / |

| Total chlorine (ppm) | / | / | 100max |

| Proportion | 1.1501.180 | ||

Cycloaliphatic Epoxy | TTA21P | Parts | 100 |

Anhydride curing agent | MHHPA | Parts | 130 |

Accelerator | AO-4 | Parts | 2 |

Viscosity | 25℃ | mPa·s | 160 |

Thermal properties | Tg-DSC | ℃ | 226 |

△H | J/g | 350 | |

Peak temperature | ℃ | 195 | |

Tg-TMA | ℃ | 225 | |

α1 | μm/(m·℃) | 56 | |

α2 | μm/(m·℃) | 174 | |

Tg-DMA E' | ℃ | 189 | |

E | ℃ | 208 | |

tanδ | ℃ | 231 | |

Mechanical property | Impact strength | KJ/㎡ | 5.95 |

Flexural strength | MPa | 125 | |

Flexural modulus | MPa | 3120 | |

Tensile strength | MPa | 57 | |

Tensile modulus | MPa | 3205 | |

Elongation at break | % | 2.8 | |

Klc | Mpa*m1/2 | 0.45 | |

Electrical properties | Volume resistivity | Ω*cm | 1.168×1016 |

Surface resistivity | Ω | 1.191×1015 | |

Dielectric constant | C2/(N*M2) | 3.0752 | |

Dielectric loss | / | 0.0042 | |

Durometer | Shore D | / | 89 |

Water absorption | 25℃/24hr | % | 1.05 |

Curing conditions | 100℃x2hr+140℃×2hr+180℃×1hr | ||

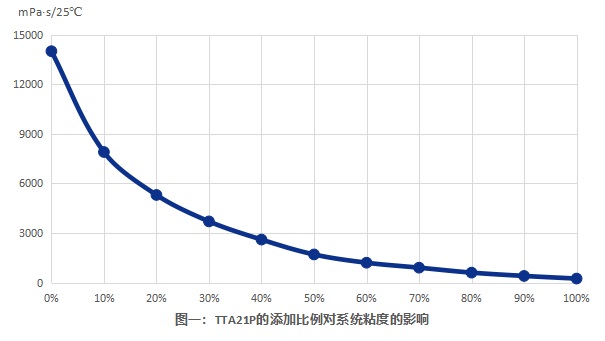

Test material: TTA21P/128

Conclusion: With the increase of TTA21P addition ratio, the system viscosity decreases rapidly, and the dilution effect of TTA21P is very obvious.

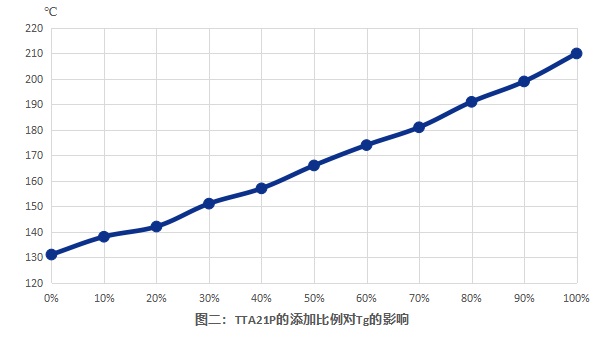

Test materials and curing conditions: TTA21P/128/MHHPA/BDMA, 100℃×2h+140℃×2h+180℃×1h.

Conclusion: With the increase of TTA21P addition ratio, the Tg value of the cured product increased significantly, which shows that TTA21P can significantly improve the heat resistance of the material.

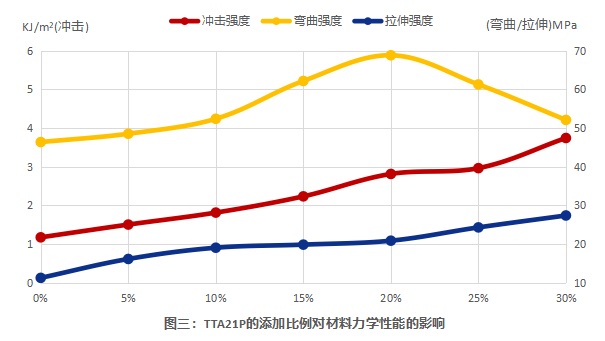

Test materials and curing conditions: TTA21P/128/MHHPA/BDMA, 100℃×2h+140℃×2h+180℃×1h.

Conclusion: As the addition ratio of this specialty resin chemical gradually increases in the range of 0%-30%, the impact strength and tensile strength of the material continue to increase, and the bending strength first increases and then decreases (reaching the maximum value at around 20%).

In summary, the best comprehensive performance can be achieved when the cycloaliphatic epoxy resin TTA21P by cycloaliphatic epoxy resin manufacturers is added in the system in a ratio of 10%-30%. The specific ratio is determined by the various indicators and requirements of the complete formula.