Metal packaging is a crucial subdivision of the national light industry, indispensable in the development of industrial production and social life. With the iteration of modern commercial needs, the requirements for metal packaging are no longer limited to providing reliable storage conditions for contents. From the perspective of an information carrier, manufacturers hope to enhance brand value, convey corporate culture, and future trends through meticulous design and perfect manufacturing.

Tinplate packaging, primarily three-piece cans, serves as the most typical representation. Through a series of operations on the surface treatment, cutting, printing, and welding of metal substrates, packaging products that meet specific design requirements can be obtained. Currently, the inner and outer coatings used in traditional coating processes generally require thermal baking and VOC centralized treatment, making printing factories typically significant energy consumers and VOC emitters. Given increasingly stringent emission reduction regulations, adopting green coating technology to reduce VOCs and energy consumption and achieving carbon footprint traceability is a critical issue for industry-leading companies and influential brands, whether to fulfill social responsibilities or further expand production capacity.

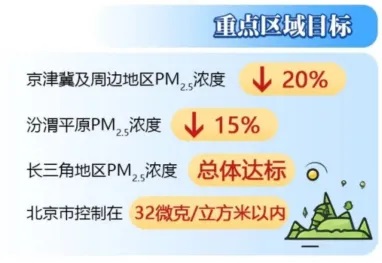

*The State Council issued the "Continuous Improvement of Air Quality Action Plan" in December 2023, targeting air quality control goals in key regions by 2025.

*The "Interim Regulations on Carbon Emission Trading Management" began implementation in China on May 1, directly linking carbon emissions to enterprise operation expectations.

*There have been several cases of penalties related to carbon emissions in 2023, with increased enforcement this year.

According to market information, in printing and coating processes, most printing inks have already been switched to UV inks, while inner coating, base coating, and varnish are still solvent-based coatings that require thermal baking. Given the specificity of inner coatings, the next technological direction should be the transition of base coatings and varnishes to photoinitiated curing technology. Currently, photoinitiated curing printing varnish is a hot topic in the industry, with rapid development progress. The following content provides detailed information on photoinitiated curing printing varnish.

Ultraviolet photoinitiated cationic (UV cationic) coatings are currently the most suitable green coating products for tinplate packaging. Their technical features, such as food contact safety, excellent post-processing performance, zero VOC emissions, no need for heating, and ultra-high curing efficiency, perfectly cover product needs. Currently, leveraging their leading photoinitiated curing application technology, Europe and America have been commercially using this technology for years. With the spread of technology and the reduction of comprehensive costs, the market penetration rate of UV cationic printed coatings is expected to further increase in the future.

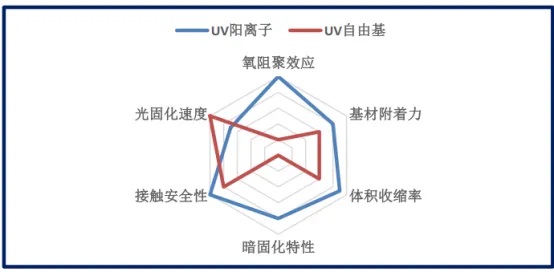

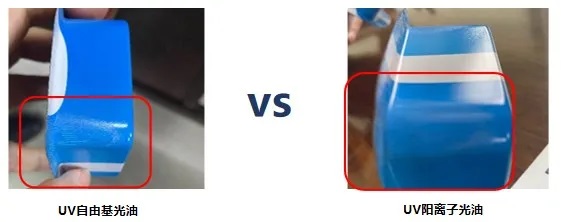

Ultraviolet photoinitiated free radical (UV radical) coatings are another common photoinitiated curing system. The core difference in their application in printing on tinplate is that the Cationic UV coating can be used for all types of tinplate packaging, while UV radical coatings cannot be used for food and high-stretch packaging. What causes the differences in application scenarios? The following further discusses this:

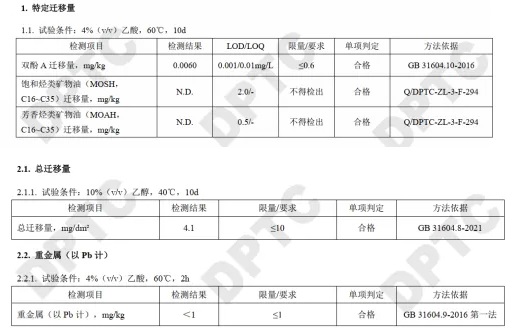

Chart 1: Comparative Characteristics of UV Cationic and UV Radical Systems

The curing mechanism of this specialty resin chemical is the process of small molecules polymerizing into large molecules in a very short time. UV cationic coatings have a conversion rate close to 100%, and the cured film material has good low migration characteristics. In contrast, the radical system typically achieves only about 80% conversion. The residual small molecules from unreacted components fail to meet safety requirements.

The reason for the ultra-high conversion rate of UV cationic coatings is that monomers or resin molecules in the system often have two or more functional groups. These have post-curing (or dark curing) characteristics. Under UV light irradiation, they trigger polymerization and chain reactions. In an extremely short time (about 0.02 seconds), the conversion rate of functional groups can exceed 80%. The remaining unreacted functional groups continue reacting even without UV energy. At room temperature for 48 hours, the conversion rate can exceed 99%, and heating can significantly shorten this time.

Chart 2: Typical Values of Low Molecular Migration in UV Cationic Coatings

This fundamentally differs from the curing mechanism of UV radical systems. Under UV light irradiation, UV radical functional groups achieve about 80% conversion, and the reaction stops immediately after the UV light is cut off. Unreacted monomers, functional groups, and resins remain in the film material, which diminishes mechanical performance and durability and easily migrates to the contact surface, posing safety risks.

Moreover, UV cationic coatings have low volatility and odor, providing a better operational environment and health safety, making them more acceptable to production line operators.

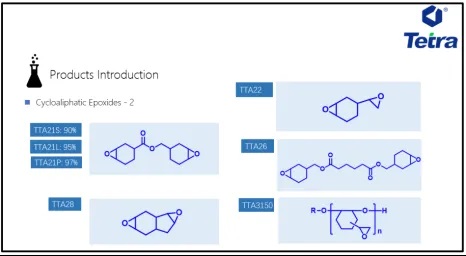

The primary resins used in the UV cationic system are epoxy materials, which provide excellent adhesion and mechanical strength inherent in epoxy materials. Engineers can select from alicyclic epoxies, bisphenol A epoxies, hydrogenated epoxies, and oxirane rings based on specific application scenarios. Cycloaliphatic epoxy resins have the highest reactivity, a high Tg, do not contain bisphenol A, and overcome the poor weatherability of ordinary epoxy materials, making them the most suitable epoxy resin materials for cationic reactions.

UV cationic varnish has the following characteristics:

High Stretchability

The volumetric shrinkage during cationic curing is low, which helps reduce internal stress during curing, thereby lowering the material's brittleness and increasing toughness.

Boiling and Chemical Resistance

UV cationic varnish, primarily based on alicyclic epoxy, does not contain benzene rings or other molecular structures that affect weatherability. The high cross-linking density provides high Tg, giving the coating excellent chemical and boiling resistance.

High Mechanical Strength

During cationic curing, the active cationic centers generated by cationic initiators trigger the ring-opening polymerization of epoxy groups in the resin, forming a three-dimensional network structure. Unlike the free radical system's acrylate base, the high-density saturated cycloaliphatic structure imparts high cross-linking density and excellent mechanical properties to the cured product, enhancing material strength and scratch resistance.

UV Cationic Printing Varnish | UV Radical Printing Varnish | |

Stamping Performance | No loss of gloss under moderate depth | Significant loss of gloss at depth |

High-Temperature Boiling | No bubbling or peeling after 130°C/60 minutes of high-temperature steaming | Bubbling and peeling under high-temperature steam |

Table: Comparison of Toughness in Stamped Cans

Chart: Performance of UV Cationic Coating in Three-Piece Can Varnish Applications

Having discussed the importance of photoinitiated curing printing varnish and the differences between products, the most practical issue is how project investment in photoinitiated curing compares to traditional coating. Previously, due to higher costs of coatings and equipment, market development of photoinitiated curing coatings was slow. In recent years, with significant cost reductions in these two areas, the explicit cost of projects is now on par with traditional coating, and combined with the huge advantages in implicit costs, the overall cost of projects shows an absolute advantage.

Cost Type | UV Cationic Varnish | UV Radical Varnish | Traditional Solvent Varnish | |

Explicit Cost | Energy Cost | Low | Low | High |

Coating Cost | Slightly High | Slightly High | Low | |

Management Cost | Low | Medium | High | |

Equipment Investment | Low | Low | High | |

Implicit Cost | Applicability | Wide | Limited | Wide |

VOC Reduction | Advantage | Advantage | Pain Point | |

Flexible Scheduling | Easy | Easy | Difficult | |

Operating Environment | Good | Good | Poor | |

*Comprehensive Cost Comparison Between Different Types of Varnishes

The biggest change in photoinitiated curing printing equipment is the need to install UV lamp sources on the production line, replacing traditional ovens. This significantly reduces equipment investment and footprint, and natural gas is no longer needed to provide heat energy. According to professional equipment suppliers, the investment for a new photoinitiated curing line (excluding coating) does not exceed 1 million RMB.

*Diagram of Photoinitiated Curing Printing Line (provided by supplier)

UV cationic printing varnish is maturely applied in tinplate packaging abroad. Domestically, cationic varnish already holds a comprehensive cost advantage. Although the number of photoinitiated curing coating equipment in the domestic market is limited, downstream manufacturers are actively expanding layouts, choosing between UV cationic or UV radical varnish based on their business structure. Additionally, UV cationic varnish is also applicable to aluminum substrates, including aluminum cans and aluminum screw caps.

UV cationic clear base oil and white coating products are still under development, with few commercial varieties available on the market.

The previous introduction discussed alicyclic epoxy as the preferred resin type for UV cationic varnish. The following are common types of alicyclic epoxy resins on the market. By varying structures, the toughness, adhesion, heat resistance, viscosity, and other properties of the varnish can be adjusted, and systems can be matched according to different application scenarios:

Chart 4: Introduction to Some Alicyclic Epoxy Resin Products by TETRA Material.

Jiangsu TETRA New Material Technology Co., Ltd. is a high-tech enterprise specializing in the production, development, and technical service of alicyclic epoxies and specialty epoxy resins. They have a high-quality R&D team consisting of professionals and technological management talents who have long been engaged in technical applications in the chemical and pharmaceutical fields. Currently, they have two production bases in Taixing, Jiangsu and Dongying, Shandong, with a total capacity of about 15,000 tons.

We welcome communication and exchanges with industry partners to contribute to the development of photoinitiated curing technology in China.